Ulven Forgings/Ulven Companies

Ulven Forgings/Ulven CompaniesRequest A Quote

Hubbard, OR | 503-982-9779https://www.ulvencompanies.com/

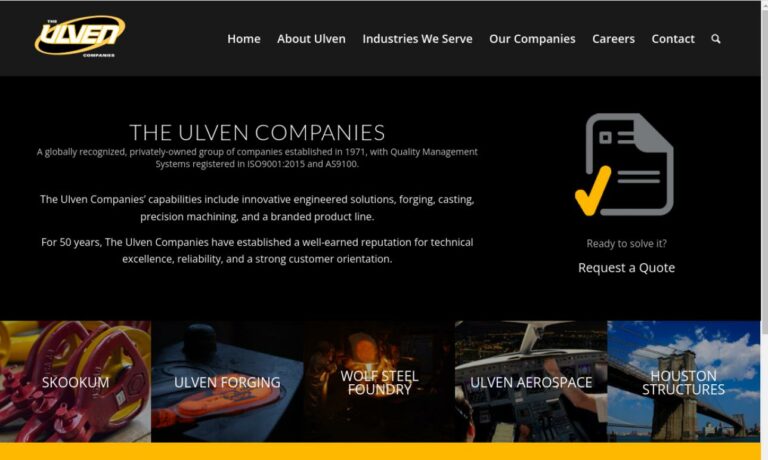

Ulven Forgings, also known as Ulven Companies, is a leading manufacturer of forged components and products. The company specializes in producing high-quality forgings for a variety of industries, including oil and gas, aerospace, construction, transportation, and defense. The company has been in business for over 30 years and is known for its commitment to quality, innovation, and customer service. With a team of experienced engineers and technicians, Ulven Forgings can design and produce custom forgings to meet the unique needs of each customer. The company's products range from simple forged components to complex assemblies and systems. Ulven Forgings offers a wide range of forging capabilities, including open-die forging, closed-die forging, and rolled-ring forging. The company can produce forgings in a variety of materials, including carbon steel, alloy steel, stainless steel, aluminum, and titanium. The company's advanced manufacturing processes ensure that each forging meets the highest standards for strength, durability, and reliability. In addition to its forging capabilities, Ulven Forgings offers a range of value-added services, including machining, heat treating, and testing. The company's in-house machining capabilities allow it to provide finished components and assemblies, reducing the need for additional processing by customers. The company's heat treating capabilities ensure that each forging has the desired mechanical properties, while its testing capabilities ensure that each product meets or exceeds industry standards for quality and performance. Ulven Forgings is committed to sustainability and environmental stewardship. The company has implemented a number of initiatives to reduce its environmental footprint, including waste reduction, energy conservation, and recycling. Ulven Forgings is also committed to the health and safety of its employees and has implemented comprehensive safety programs and training to ensure a safe working environment. Overall, Ulven Forgings is a leading manufacturer of high-quality forgings and components, with a commitment to quality, innovation, and customer service. Its advanced manufacturing processes, value-added services, and commitment to sustainability make it a trusted partner for customers in a variety of industries.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services