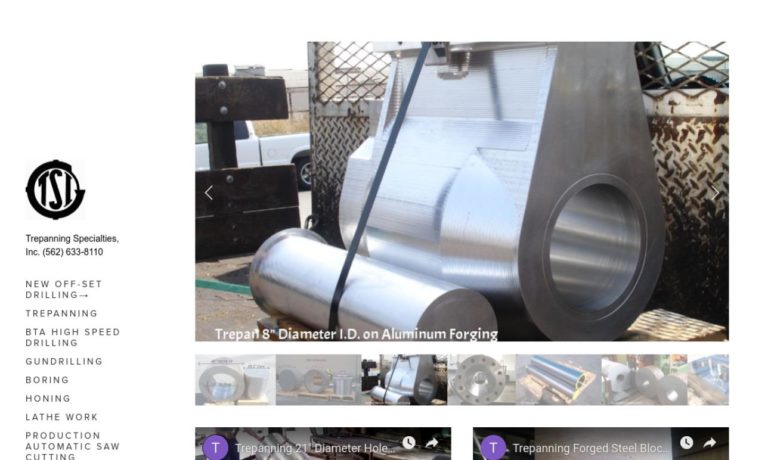

Trepanning Specialties, Inc.

Trepanning Specialties, Inc.Request A Quote

Paramount, CA | 562-633-8110https://www.trepanningspec.com/

Trepanning Specialties, Inc. is a leading supplier of precision forging services, catering to a diverse range of industries. With a strong foundation dating back to 1973, the company has built a stellar reputation for delivering exceptional quality and service. Specializing in the art of forging, Trepanning Specialties possesses a deep understanding of metallurgy and a wealth of experience in shaping various metals to meet exact specifications. Our expertise extends to a wide range of materials, including stainless steel, carbon steel, aluminum, titanium, and more. We serve industries such as aerospace, automotive, oil and gas, defense, and power generation. Equipped with state-of-the-art forging equipment, including hydraulic presses, hammers, and specialized tools, Trepanning Specialties ensures precision and efficiency in every forging process. Our skilled technicians and engineers employ advanced techniques to shape and mold metal components according to the unique requirements of each project. From small-scale prototypes to large production runs, we deliver superior forged components with unmatched strength, durability, and precision. As a customer-centric organization, we recognize the importance of tailored solutions. Trepanning Specialties works closely with clients to understand their specific forging needs and develop customized strategies to fulfill them. Our team collaborates with clients throughout the entire forging process, from design and prototyping to production and delivery. We take pride in providing flexible order quantities, competitive pricing, and fast turnaround times. Quality is at the heart of everything we do. Trepanning Specialties maintains a comprehensive quality management system that upholds the highest standards of excellence, reliability, and performance. We are proud to be ISO 9001 certified, which exemplifies our commitment to delivering products of exceptional quality. Additionally, our AS9100 certification underscores our dedication to meeting the rigorous quality standards of the aerospace industry. At Trepanning Specialties, customer satisfaction is paramount. Our dedicated team of professionals is committed to providing exceptional customer service, offering technical support and guidance at every stage of the forging process. We strive to exceed customer expectations, ensuring a seamless experience from initial consultation to final delivery. In summary, Trepanning Specialties, Inc. is a trusted provider of precision forging services. With our advanced equipment, material expertise, customized solutions, and unwavering commitment to quality and customer satisfaction, we cater to a wide range of industries. Partner with us for your forging needs and experience excellence in every aspect of the forging process.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services