The stainless steel forging process enhances stainless steel’s inherent properties, giving it a more appealing appearance and feel. In addition, the forging process improves stainless steel’s corrosion resistance, allowing it to tolerate aggressive and more extreme situations. Read More…

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

As the leaders in open-die and rolled ring forging, Scot Forge has a 127-year track record of success. From the wheels of NASA’s discovery Mars Rover, to mission critical components for nuclear submarines, to large hydraulic cylinders for the largest mining trucks on the planet, Scot Forge creates the precision forged parts used in demanding applications all over the world. Get in contact with...

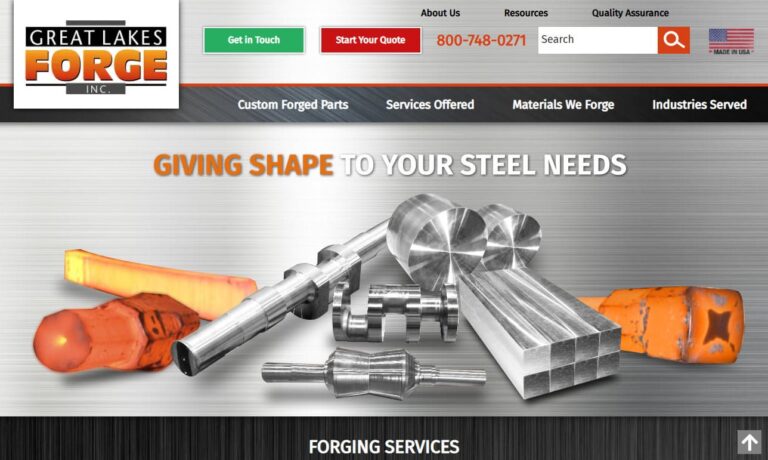

Great Lakes Forge specializes in stainless, carbon, H-13 FM open die forgings and alloy steel forgings. We produce ISO-certified blocks, bars, rounds, crankshafts and step-down shafts. We offer rough turning, milling, heat treating and testing. For more information, see our website.

More Stainless Steel Forging Companies

What are Stainless Steel Forgings?

The stainless steel forging process enhances stainless steel's inherent properties, giving it a more appealing appearance and feel. In addition, the forging process improves stainless steel's corrosion resistance, allowing it to tolerate aggressive and more extreme situations.

How Stainless Steel Forging is Done

Stainless steel forging is a method of metal forming in which the metal is heated to a malleable temperature and then molded or shaped using hammer blows or a press. For magnetic stainless steel, the forging temperature is 2003°F (1095°C); for nonmagnetic stainless steel, the forging temperature is 2102°F (1150°C).

Stainless steels are forgeable; however, because they retain their strength at forging temperatures, they generally necessitate greater hammer energy or higher intensity hammer strikes than other alloys.

Due to its outstanding corrosion resistance, stainless steel forging is used to build various manufactured parts for various industries. Stainless steel is a popular choice for cost-effective metal fabrication because of its extensive availability in most markets and high strength and ductility.

Types of Stainless Steel

There are three primary forms of forged stainless steel on the market today.

The first is pulled-out stainless steel, characterized by a lengthening of the material while the breadth is reduced. Upset stainless steel is the polar opposite of pulled-out steel, with an increased breadth and decreased length.

Finally, the closed-die method produces squeezed-in stainless steel, which allows for multi-directional flow and produces a solid, compact shape. Higher ductility, high levels of formability, increased grain uniformity and strength, prevention of strain hardening, and a reduction in chemical incongruities are all advantages of stainless steel forging.

To get the most out of the process, take precautions to avoid variances or warping during the cooling process and the possibility of air reactions with the metal.

Stainless Steel Grades

- Austenitic: This grade has good cryogenic toughness and is nonmagnetic. It also offers the strongest impact resistance of the four classes.

- Martensitic: This stainless steel grade is extremely robust and resistant to pitting corrosion.

- Hardening of precipitation: This grade has a decent fatigue life and is fairly strong and tough.

- Duplex: This grade is robust at room temperature, sturdy, and corrosion-resistant.

Advantages of Stainless Steel Forging

- A protective oxide coating is present on stainless steel open die forgings which improves corrosion resistance. Stress cracking, crevice corrosion, pitting, deformation, and other risks that might affect the life of a forged item are all avoided with these metal forgings.

- Custom stainless steel forgings can withstand lengthy exposure to corrosive conditions, including pumps, valves, chemical and petrochemical processing equipment, and maritime equipment.

- In heat exchangers, furnaces, and ovens, stainless steel forged parts maintain high heat-resistant properties.

- Components made by forging are much stronger than parts made by machining or casting because forging creates grain flow that follows the contour of the workpiece, enhancing its strength.

Applications of Forged Stainless Steel

- Construction, Agriculture, and Off-Highway: Forging can create parts for any form of outdoor equipment that needs to survive hostile settings.

- Hand Instruments: Hand tools that have been forged are often stronger and more durable than those that have been cast.

- Recreation and Sports: Sports equipment, such as golf clubs, and recreational equipment, such as garden tools, are frequently made from stainless steel forgings.

- Oil Industry: Special application wrenches in the oil industry are usually made from stainless steel forgings.

- Rails: Forged parts are appropriate for railways because of their strength and endurance.

- Defense and Firearms: Forgings made of stainless steel can be used to make cannon parts and missile guiding systems.

- Aerospace Industry: Stainless steel forgings are perfect for the aircraft sector because of their strength and adaptability.

- Gearboxes: Stainless steel forgings are extremely versatile and can be utilized to make a wide range of long-lasting gear components.

- Medical Industry: Forged stainless steel components' excellent corrosion resistance makes them perfect for the medical industry, as forged products like surgical instruments can be sterilized repeatedly.

- Marine Industry: Stainless steel forging is good for marine applications such as nuts, bolts, screws, and pliers due to its corrosion resistance.

Choosing the Right Stainless Steel Forging Manufacturer

To ensure the most positive outcome when purchasing stainless steel forgings from a stainless steel forging manufacturer, it is important to compare several companies using our directory of stainless steel forging manufacturers. Each stainless steel forging manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each stainless steel business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple stainless steel forging companies with the same form.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services