The outside dimensions of seamless rolled rings can range from a few inches to 30 feet, height can reach from less than an inch to higher than 9 feet, and weight can be as much as 350,000 pounds. The shape of seamless rolled rings can be configured to be flatter, like a washer, or to have high walls like a hollow cylinder. Read More…

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

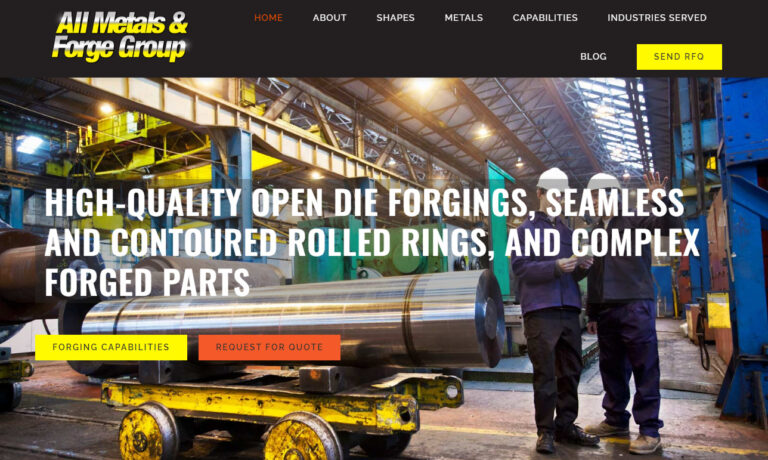

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

At Lenape Forged Products Corp., we take immense pride in our legacy of delivering high-quality forged products to a diverse array of industries. We specialize in producing precision-forged components that meet the rigorous standards required by our clients. Our extensive range of forgings includes everything from intricate custom parts to high-volume, standardized components, all meticulously...

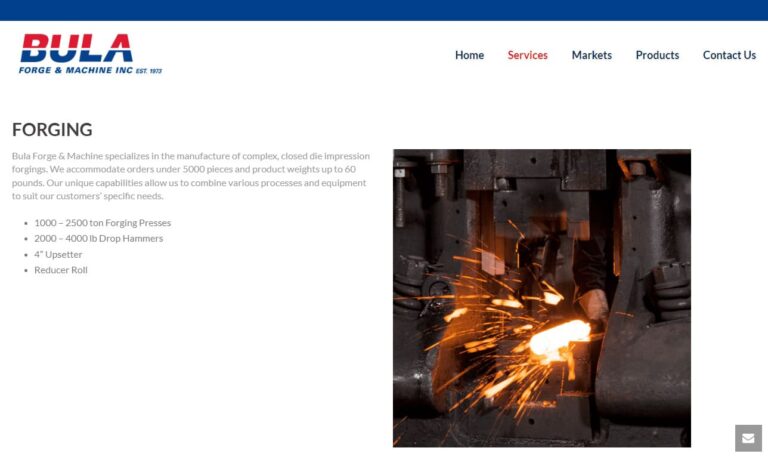

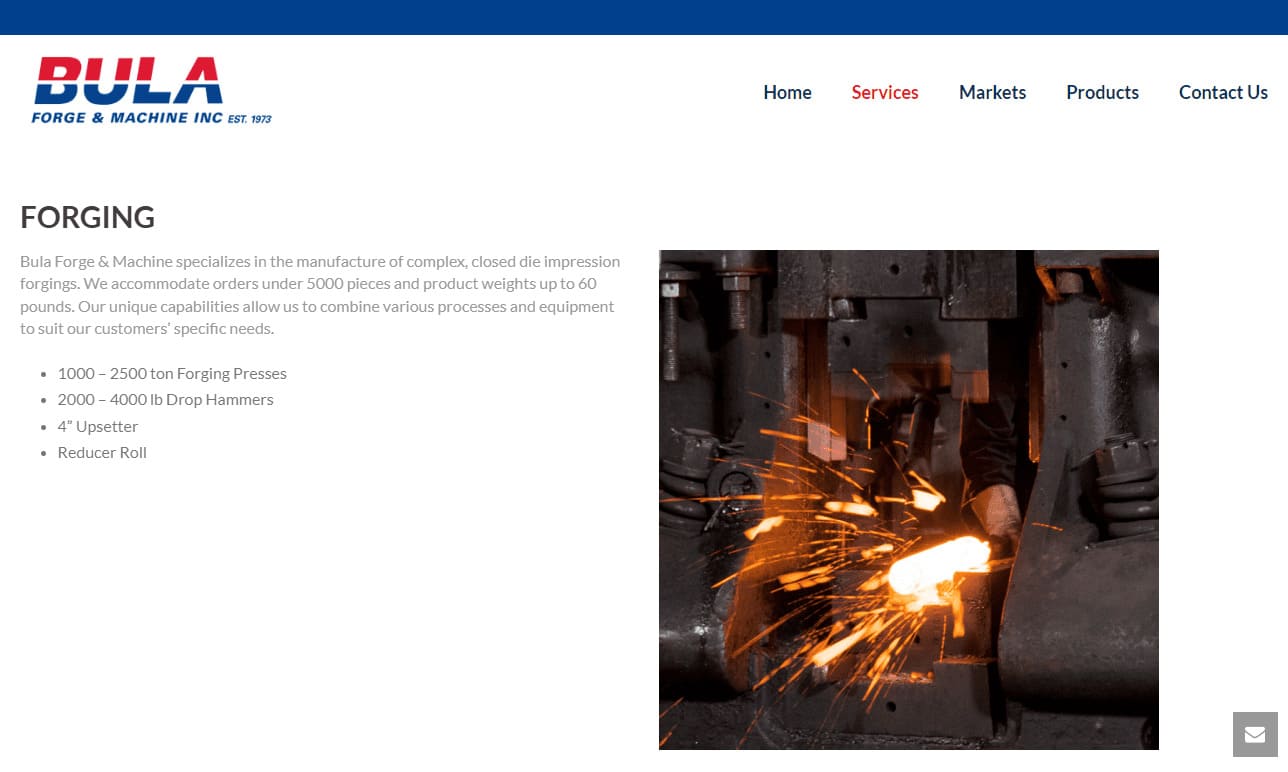

At Bula Forge & Machine, Inc., we are dedicated to delivering exceptional forging solutions that cater to a wide range of industries. Our expertise in the field of forgings is driven by a commitment to precision, innovation, and superior craftsmanship. We specialize in producing high-quality forged components that meet the rigorous demands of our clients.

More Seamless Rolled Ring Companies

Unlike other types of ring forming, this forging process creates a seamless ring with great integral strength, capable of resisting high degrees of internal or external pressure. This is why wheel hubs, bearing housings, pressure vessels, gears, jet engine bearings, engine turbines and wind turbines - all applications which apply significant force - are usually made from seamless forged rings.

Seamless rolled rings are also utilized in nuclear reactors, off-road equipment, couplings, rotor spacers, sealed discs and cases, flanges, valve bodies and many other high stress applications.

A seamless rolled ring begins as a solid, circular block of metal that is heated to forging temperatures and then punched through the center to form a "donut" shape. This preform is then placed on a rolling rig with a roller touching the inside of the donut and a roller touching the outside of the donut. The two rollers begin to rotate in opposite directions, turning the ring, and at the same time the rollers slowly squeeze inwards, thinning the ring wall and causing the diameter of the ring to increase.

Some ring-rolling machines also have a roller that presses down on top of the ring as it turns, governing the height of the ring wall. The process continues until the ring has been thinned, flattened or otherwise shaped to its desired dimensions, at which point it may receive secondary processing such as size fine-tuning or heat treatment. Rings can be shaped at high forging temperatures for faster forging or, for rings that require the highest pressure resistance, such as aluminum car wheels, the rolling can be done at lower temperatures over a longer period.

Lower forging temperatures and longer forging times result in greater tensile strength. The ring-rolling process can be modified in any number of ways to produce a wide range of precise contours both on the inner dimension and outer dimension. Seamless rolled rings are unequaled in tangential strength, ductility, and adaptability.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services