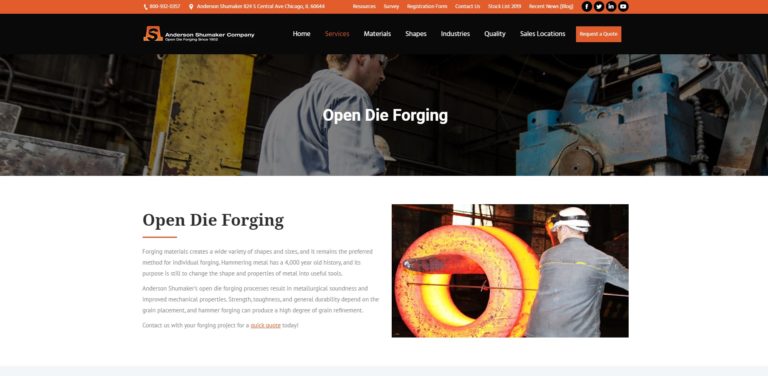

Open die forging is the process of bending metal pieces or workpieces into a desired shape using open dies. The material is formed during this forging process by positioning the workpiece on a stationary anvil and using a power hammer to strike it. Open-die forging is not the final process; secondary machining procedures help shape the material further. Read More…

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

As the leaders in open-die and rolled ring forging, Scot Forge has a 127-year track record of success. From the wheels of NASA’s discovery Mars Rover, to mission critical components for nuclear submarines, to large hydraulic cylinders for the largest mining trucks on the planet, Scot Forge creates the precision forged parts used in demanding applications all over the world. Get in contact with...

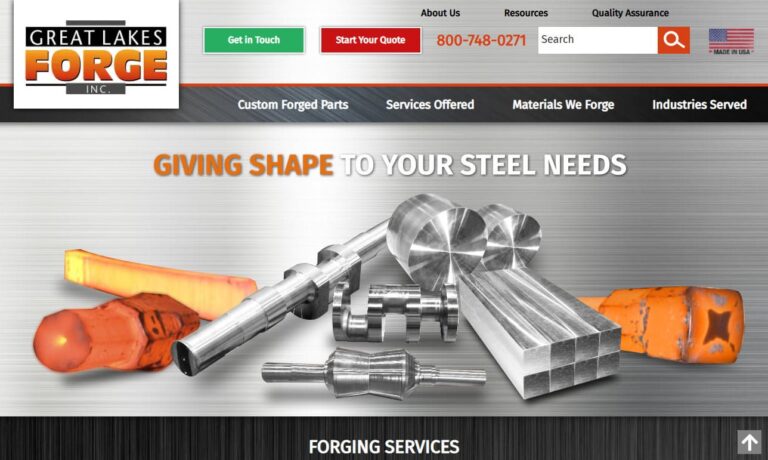

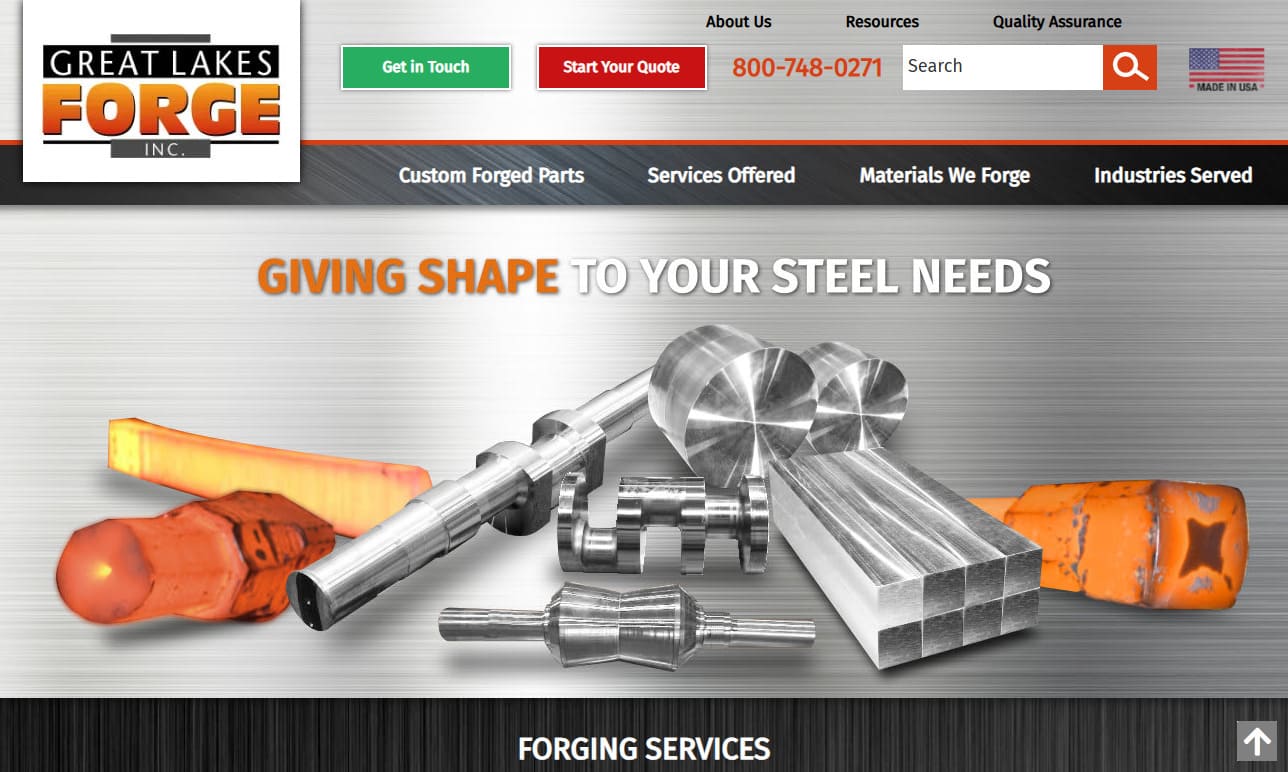

Great Lakes Forge specializes in stainless, carbon, H-13 FM open die forgings and alloy steel forgings. We produce ISO-certified blocks, bars, rounds, crankshafts and step-down shafts. We offer rough turning, milling, heat treating and testing. For more information, see our website.

More Open Die Forging Companies

Open-die forging suits art smithing, custom work, and short runs. In rare instances, ingots may be rough-shaped using an open-die forge to prep them for following operations. Manufacturers may orient the grain during open-die forging to boost strength in the desired direction.

Open-die forging has uses besides shaping metal. It reduces porosity (small air bubbles), aligns the metal’s grain, and strengthens the metal. Open-die forging can make metals more responsive to machining. Forged metal parts have better wear resistance.

Open Die Forging Primary Components:

Manufacturers use a ram or a hammer to exert force on workpieces. To give the workpiece the desired shape and size, a die is attached to the hammer or ram that makes contact with the workpiece. In open die forging, the die may have flat, concave, or convex surfaces, or it may be a tool for drilling holes or removing parts. Before hammering, the metal workpieces are heated until they are red hot. During the hammering, the workpiece is supported by this immovable anvil.

Open Die Process

Convex and concave dies are used in the presses used in the open die process. They are sometimes referred to as standard press dies. In order to ensure that the material has sufficient plastic flow properties, heat must be generated and applied. Heat will also help to lessen the force needed to create different shapes.

The material is supported by the bottom die as the higher die applies a series of strokes. During the various phases of the strokes, the material's placements are changed using a manipulator. The workpiece is free to change its direction at any time during this procedure. A force is applied in the axial direction, which is also known as the direction of the top die. This procedure can be effectively run by switching the axial direction or rotating the workpiece itself.

Open Die Forging Procedures

Operation of Cogging

The cogging process is renowned for successfully using thin dies. These dies could have a flat, V, convex, or concave shape. The ingot is reduced and elongated repeatedly and occasionally rotated. Cogging consolidates ingot flaws like holes and porosity by altering the metal's grain structure.

Drawing (Solid Forging)

Drawing is the forging process of making a shape with a length significantly bigger than its cross-section.

Manufacturers do so by lengthening the bloom or ingot or shortening the segment.

Upsetting operation

Working with the stock while referring to its axis in the vertical position is part of the upsetting operation. This position is maintained beneath the forging press's hammer. The procedure shortens the axial length while widening the stock's cross-section. Because of the enormous cross-sectional area of the workpiece, the upsetting method uses flat dies the most.

Applications of Open Die Forging

- Open die forging produces simple parts, including discs, shafts (including step shafts or shafts with flanges), hubs, blocks, cylinders, sleeves, flats, rounds, hexagons, and other custom forms.

Advantages of Open Die Forging

Open-die forging increases the strength of metal workpieces. It gives products a better microstructure, smaller grains, and continuous grain flow. Open-die forging decreases material waste and can produce items weighing up to 150 tons.

Choosing the Correct Open Die Forging Company

To make sure you have the most constructive outcome when purchasing Open Die Forging from an Open Die Forging Company, it is important to compare at least 4 Companies using our list of Open Die Forging companies. Each Open Die Forging Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Open Die Forging company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Open Die Forging companies with the same message.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services