McInnes Rolled Rings

McInnes Rolled RingsRequest A Quote

Erie, PA | 800-569-1420https://www.mcinnesrolledrings.com/

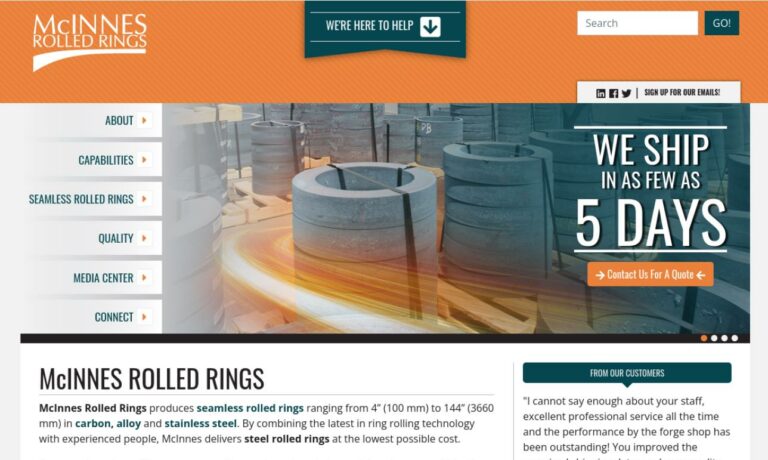

McInnes Rolled Rings is a leading manufacturer of high-quality rolled rings, open-die forgings, and seamless contoured rolled rings with over 100 years of experience in the industry. Based in Erie, Pennsylvania, McInnes Rolled Rings specializes in the production of precision-engineered products, serving a wide range of industries including aerospace, defense, oil and gas, and more. The company operates advanced manufacturing facilities equipped with the latest forging technology, including radial and axial ring rolling mills, as well as a full range of heat treating, machining, and testing capabilities. McInnes Rolled Rings' ring rolling capabilities enable the manufacture of seamless rolled rings in a wide range of sizes and shapes, while their open-die forging capabilities allow them to produce large, complex forgings. McInnes Rolled Rings' products are designed to meet the most stringent industry standards and are used in critical applications where reliability, performance, and safety are essential. These products include aircraft engine components, oil and gas industry parts, and other high-stress applications. In addition to its forging capabilities, McInnes Rolled Rings also offers value-added services such as design and engineering support, metallurgical testing, and supply chain management. This allows the company to provide complete, turnkey solutions to its customers, from initial design and engineering to finished parts. McInnes Rolled Rings is committed to providing the highest levels of quality and customer service, and is certified to ISO 9001:2015 and AS9100D. The company also has numerous industry certifications, including ITAR and DFARS. Overall, McInnes Rolled Rings is a premier provider of forging products and services, with a reputation for excellence in quality, reliability, and customer satisfaction. The company's advanced facilities, cutting-edge technology, and experienced staff make it an ideal partner for any industry looking for high-quality, precision-engineered forged components.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services