FRISA

FRISARequest A Quote

Laredo, TX | 888-882-0959https://www.frisa.com/en/welcome

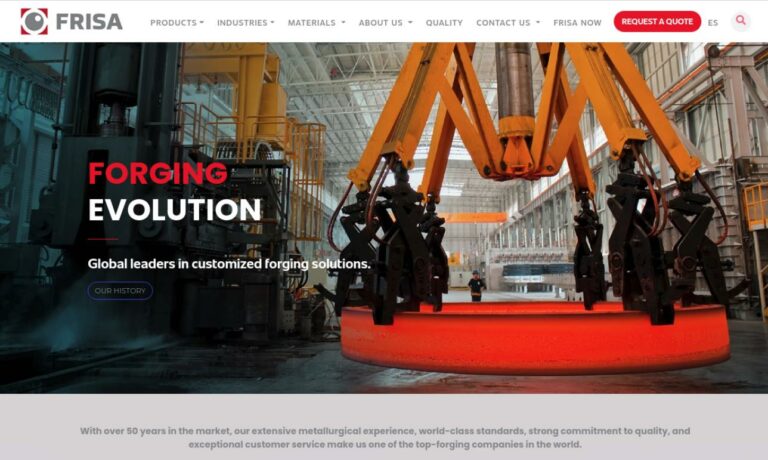

FRISA is a leading manufacturer of high-quality forged products, including seamless rolled rings, discs, and complex forgings, for a wide range of industries, such as aerospace, energy, defense, and industrial markets. The company was founded in 1971 in Laredo, Texas, and has since expanded to become a global leader in the forging industry. FRISA offers a range of forging services, including open die, closed die, and ring rolling. The company's state-of-the-art facilities and skilled workforce allow it to produce forged products in a variety of materials, including alloy steel, stainless steel, titanium, and nickel alloys. FRISA's extensive knowledge and experience in metallurgy and forging techniques enable it to manufacture custom-made products according to customers' specifications. In addition to forging, FRISA offers a full range of value-added services, such as heat treatment, machining, and testing. The company's heat treatment capabilities include annealing, normalizing, quenching, and tempering, among others. Its machining capabilities include CNC turning, milling, drilling, and grinding, as well as manual machining for smaller, more complex components. FRISA's testing capabilities include non-destructive testing, such as ultrasonic and magnetic particle inspection, as well as mechanical testing, such as tension and compression testing. FRISA is committed to quality and has a comprehensive quality management system in place to ensure that all products meet the highest standards for safety, reliability, and performance. The company's quality control procedures include extensive testing and inspection throughout the manufacturing process, from raw materials to finished products. FRISA is certified to various quality standards, including ISO 9001, AS9100, and Nadcap. FRISA's experienced and knowledgeable staff work closely with customers to provide them with customized solutions that meet their unique needs and requirements. The company's engineering team can assist customers with product design, material selection, and process optimization to ensure that their products are of the highest quality and performance. Overall, FRISA is a trusted and reliable partner for customers in need of high-quality forged products. With its advanced technology, skilled workforce, and commitment to quality and customer service, FRISA is well-positioned to meet the needs of customers in a wide range of industries.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services