Modern forged rings have many uses, such as parts for machine tools, aerospace applications, turbines and pipe and pressure systems. These rings are usually forged with stainless steel, tool steel, aluminum, copper, steel alloy or the like. Read More…

For over 30 years, we have provided metal forged products for a wide variety of industries, including the aerospace, military, food service, medical, and automotive industries. Our customers know they can trust our forgings for quality and affordability.

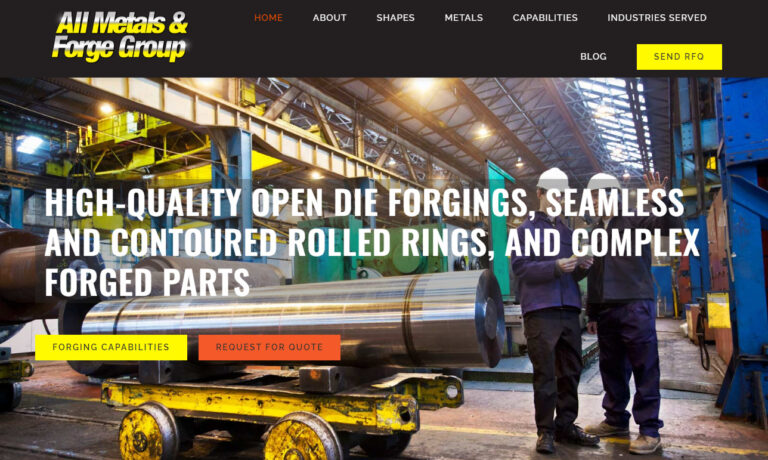

All Metals & Forge Group is your ISO9001:2015 and AS9100D registered forging facility. All Metals provides a wide range of materials, products and services, including discs, shafts, sleeves, cylinders, plates, blocks and many other shapes, both stock and custom, satisfying all of their customers’ requirements. Give All Metals & Forge Group a chance to satisfy your needs— you’ll be glad you...

Although we have over 100 years of experience, we are committed to continually expanding our offerings in all industries. We are not content to remain as we are, but we continually work to improve our products and processes each and every day.

At Lenape Forged Products Corp., we take immense pride in our legacy of delivering high-quality forged products to a diverse array of industries. We specialize in producing precision-forged components that meet the rigorous standards required by our clients. Our extensive range of forgings includes everything from intricate custom parts to high-volume, standardized components, all meticulously...

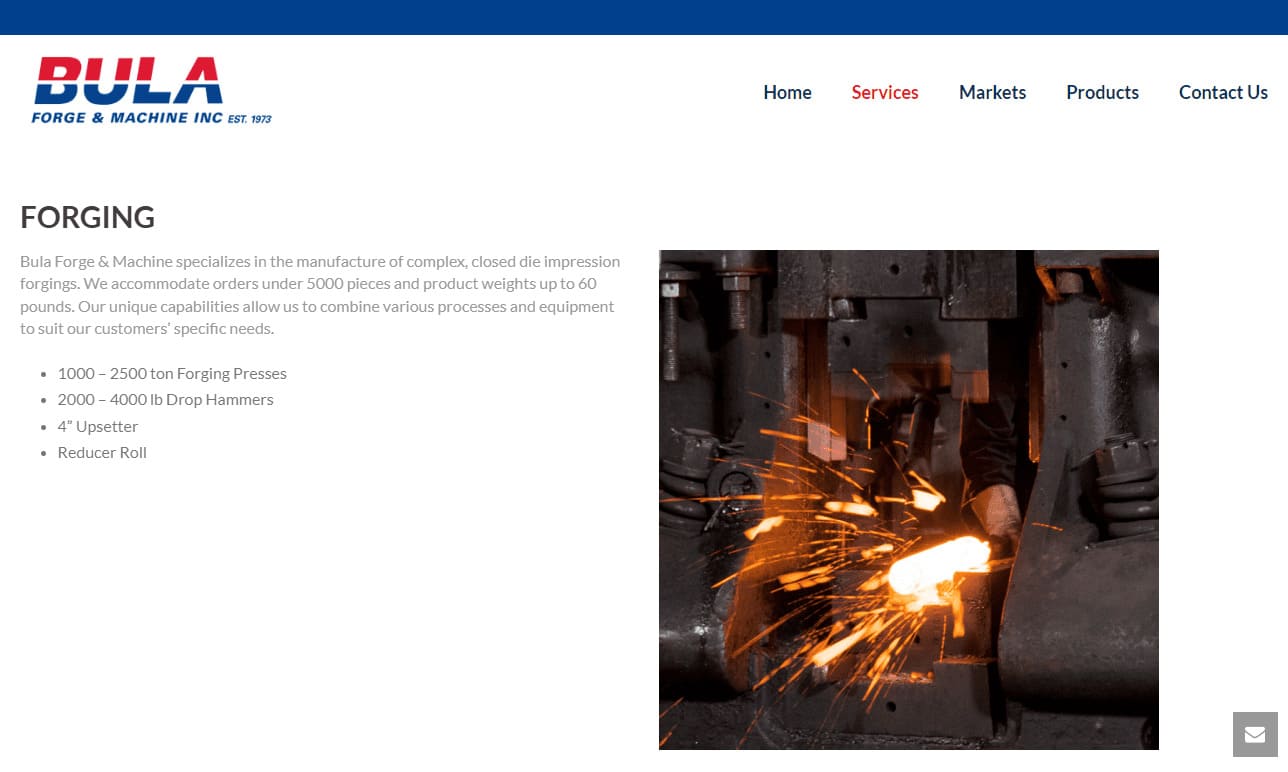

At Bula Forge & Machine, Inc., we are dedicated to delivering exceptional forging solutions that cater to a wide range of industries. Our expertise in the field of forgings is driven by a commitment to precision, innovation, and superior craftsmanship. We specialize in producing high-quality forged components that meet the rigorous demands of our clients.

More Forging Ring Companies

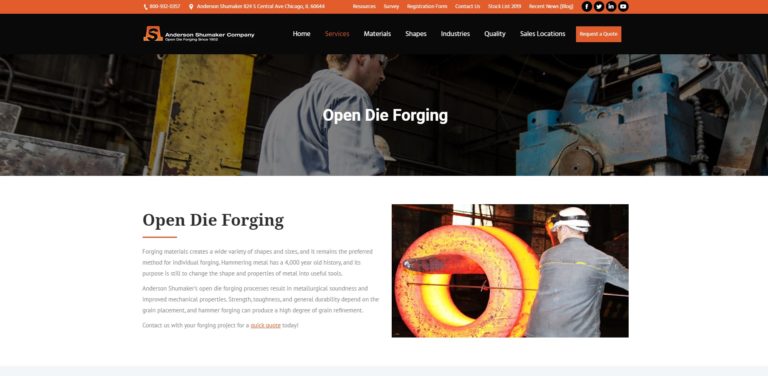

Using one method of forging, a stock is first cut to length, upset and then pierced through the middle to create a hole in the center. (The process of upsetting decreases the metal's length and increases its cross-section.) After being pierced, the piece is placed on a mandrel or saddle, where the shape is formed by the up and down motion of a forging die. The forging die hammers the metal from above, as the work is rotated incrementally in a series of steps meant to eventually achieve the ring's final size.

Another method of forging rings is called roll forging. In roll forging, a round or flat bar is increased in length and decreased in thickness through the use of two cylindrical or semi-cylindrical rolls, each containing one or more shaped grooves. A heated bar is inserted into the rolls, which rotate when the bar hits a certain spot, progressively shaping the bar as it rolls.

The bar is then inserted into the next set of grooves, or returned to the same grooves, where the process repeats. This goes on until the intended shape and size of the piece is achieved. The process of ring rolling produces seamless rings.

Forging rings, compared to casting or machining them, is an expensive and laborious process. However, forging rings can still be advantageous because the work produced will have superior strength. This superior strength exists because its grain is continuous, due to the fact that, as the metal is shaped during the forging process, its grain deforms to adapt the general shape of the piece.

Furthermore, a ring that is not forged runs the risk of compromised corrosion resistance and shape distortion, and it may require more repair down the line. For a ring that will stand the test of time, forging is the way to go.

Die Castings

Die Castings Forgings

Forgings Grey Iron Castings

Grey Iron Castings Investment Castings

Investment Castings Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services